Cornell researchers have put a new spin on measuring and controlling spins in nickel oxide, with an eye toward improving electronic devices’ speed and memory capacity.

Their paper, “Spin Seebeck Imaging of Spin-Torque Switching in Antiferromagnetic Pt/NiO Heterostructures” was published Oct. 22 in Physical Review X.

One of the specialties of senior author Greg Fuchs, associate professor of applied and engineering physics, is spintronics – the study of the spin (a type of angular momentum that can record information) that is responsible for the magnetic properties of electrons. Fuchs and his group are striving to understand how to measure and manipulate this magnetism.

Rather than measuring magnetism with traditional forms of magnetic microscopy – in which materials are bombarded with light, electrons or X-rays – Fuchs has pioneered a technique called magneto-thermal microscopy. In this method, heat is applied to the material in a tiny area, and magnetism in that area is gauged by the electrical voltage that is generated. This allows Fuchs’s team to see what happens when they manipulate a magnetic material’s spins.

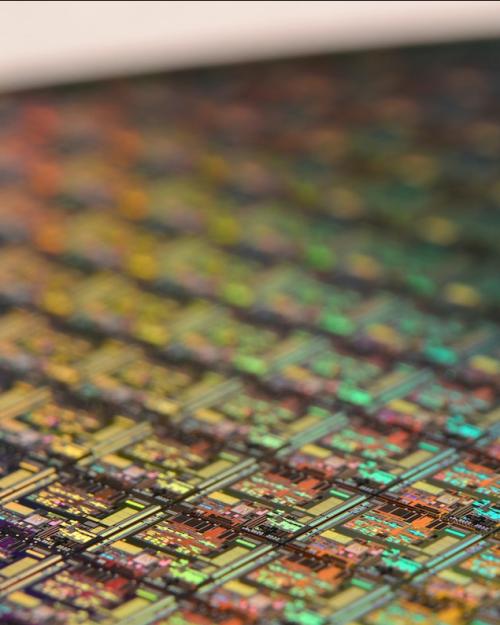

The Fuchs Group has been exploring antiferromagnetic materials, which are unique because their individual magnetic elements – the tiny pieces of material that remember bits of information based on their orientation – don’t produce a magnetic field. Therefore, they can be packed close together without disturbing each other, potentially enabling high-density storage. Antiferromagnets are even speedier siblings of ferromagnets – more conventional magnetic materials that do produce a magnetic moment. Antiferromagnets have the potential to operate a thousand times faster, according to Fuchs.

But understanding the behavior of antiferromagnetic materials isn’t easy.

“Antiferromagnetic material is hard to study because every other spin points in the opposite direction, so there is no net magnetization,” Fuchs says. “It doesn’t create a magnetic field. It’s not really amenable to conventional approaches to magnetic measurement. There are specialized X-ray facilities that can do it, but there aren’t many, and that limits the measurements that you can make. So you have very few options.”

Fuchs and his team devised a clever end-run around the problem by picking just the right kind of antiferromagnetic material – nickel oxide – which contains multiple planes of spin, with the spins in every other plane pointing in an opposite direction. In a sandwich of platinum and nickel oxide, the spins at the boundary are all aligned parallel to each other, allowing researchers to use heat flow to measure the spins’ orientation without the signal being canceled out.

This effect, called the “interfacial spin Seebeck effect,” had been previously demonstrated in ferromagnetic metals and insulators, but was only theorized for antiferromagnets. No one before had demonstrated it – let alone used it to image antiferromagnetic samples with standard tabletop lab equipment.

“Imaging antiferromagnets allows us to see microscopically how they respond to external stimuli, such as electrical current. These details are critical when trying to make antiferromagnetic memory devices,” says lead author Isaiah Gray, a Ph.D. student in applied physics.

“You normally think of antiferromagnets as a pretty hard nut. It’s surprising to me that such a relatively simple approach works,” Fuchs said. “This unlocks a whole new realm in terms of what you can do in antiferromagnetic devices. Now I can control the textures in these materials, and then see how the spins are oriented.”

Co-authors include assistant professor Katja Nowack; Daniel Ralph, the F.R. Newman Professor of Physics; Darrell Schlom, the Herbert Fisk Johnson Professor of Industrial Chemistry; postdoctoral associates Nikhil Sivadas, Gregory Stiehl and John T. Heron; applied physics Ph.D. student David Low, and researchers from Kyoto University, the University of Michigan and the National Institute of Standards and Technology Center for Neutron Research.

The research was supported by the Cornell Center for Materials Research, with funding from the National Science Foundation’s Materials Research Science and Engineering Center program, and the Japan Society for the Promotion of Science.

This story originally appeared in the Cornell Chronicle.