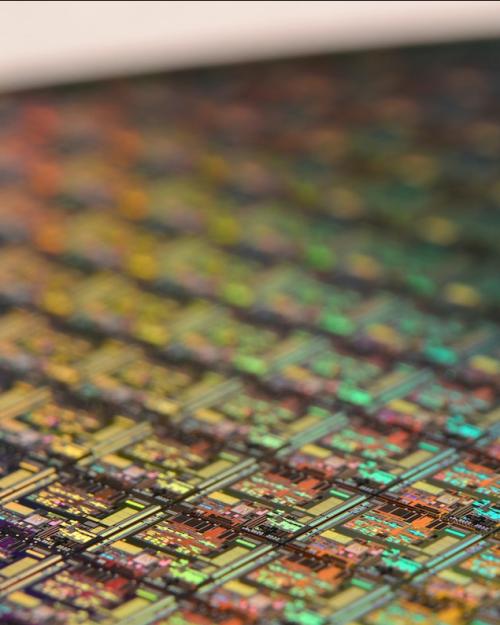

Electricity and light hold promise as sustainable inputs for some of chemistry’s biggest challenges, including drug development and environmental clean-up – if chemists can learn to harness them.

In a step toward this goal, Cornell researchers have designed a light-powered, reusable catalyst that’s pre-charged by electricity and capable of driving challenging reactions. Their findings about the connections between polymers in this type of reaction, called electrophotocatalysis, could provide the foundation for the development of sustainable catalysts to make drugs in a non-toxic way and turn environmental toxins like PFAS and greenhouse gases into useful substances.

“Polymer Connectivity Governs Electrophotoctalytic Activity in the Solid State" published Aug. 13 in Nature Chemistry. The co-corresponding authors are Phillip Milner, associate professor of chemistry and chemical biology in the College of Arts and Sciences (A&S) and Andrew Musser, assistant professor of chemistry and chemical biology (A&S). Co-first authors are Jianheng Ling, Ph.D. ’25, and doctoral student Amy L. Vonder Haar. Doctoral student Kiser Z. Colley, M.S. ’24, and former postdoctoral researcher Juno Kim also contributed.

The study is a collaboration between the Milner Lab, which designs recyclable, sustainable, inexpensive materials to turn light and electricity into value-added products, and the Musser Lab, which studies how light is involved in chemistry.

The basic idea was to charge a polymer catalyst with sunlight, which adds an electron; attach it to the molecule that needs the electron, then shine light on it to spark a reaction.

“The broader concept is having some way to charge up a catalyst – that could be electricity, it could be light, it could be some other chemical reaction – to prime it to do this very challenging reaction,” Musser said. “The way you charge it up doesn’t matter so much for how powerful the reaction is at the end. But it’s the most efficient when you do it with electricity.”

Milner said they knew at the outset that electrophotocatalysis amplifies the power of the initial catalyst; in the current study, they set out to find how. To discover how the mechanism works, Ling, a member of Milner’s group, developed a library of polymer catalysts and tested them. The flexible polymer PTCDA-en worked the best. But the others showed a range of promise, as well.

“We now understand how this catalysis works, but we also know how to make the catalyst that can do it, and it’s recyclable, sustainable,” Milner said.

The results gave two remarkable insights into the design of photoredox catalysis, overturning two previous assumptions.

First, they discovered that the charged catalyst attaches to the molecule that needs it much earlier than they’d thought.

“The picture we hold in our heads is this molecule with its reactive electron will float around for a while until it bumps into the molecule that needs it, and that’s when the chemistry happens. For that to happen, it must hold onto the energy for a long time,” Musser said. “What we discovered in these polymers that Phill’s lab made is that the catalyst is already stuck to the molecule that needs the electron transfer, so then the chemistry happens instantaneously.”

This solves a big problem, Musser said, because the catalyst doesn’t have to hold its energy for a long time; chemists can now design reactions accordingly.

Second, they discovered that messy polymers make better catalysts in this situation than well-ordered ones.

Milner and Ling thought, while creating their library of polymer catalysts, that they needed well-ordered polymers with highly accessible surface area. After doing the study, they found flexibility, rather than exact order, was most important.

“You have to be careful how you link the units together,” Milner said. “I think that’s going to be a big design principle for us moving forward.”

Together these two design principles could have very practical applications, Milner said. The polymer catalyst can be made on a large scale and could have uses in industry.

Moreover, it’s sustainable. Electricity is used to pre-charge the catalyst – electricity that could come from a solar panel capturing ambient sunlight. Also, the polymer catalyst is recyclable; it can be recovered and reused up to five times or more.

“The reactions we can target with this process are still somewhat limited,” Milner said. “We haven’t been able to push the hardest reactions yet that we’d want to. Now that we have design principles, we have to find different catalysts that follow the same rules, but are more reactive, more energetic.”

Some of those reactions could someday be used to transform PFAS or another environmental contaminant into something useful like a pharmaceutical component, for example, Milner said: “That’s the kind of work we could get to if we can make this process work well.”

This study was supported by the U.S. Department of Energy.