Recyclable plastic containers with the No. 2 designation could become even more popular for manufacturers as plastic milk jugs, dish soap containers and shampoo bottles may soon get an environmental makeover.

Cornell chemists can demonstrate how to make high-density polyethylene with better control over polymer chain lengths, which allows for improvement over physical properties such as processability and strength, according to research published Dec. 27, 2019, in the Journal of the American Chemical Society.

“The grand challenge has been to minimize the energy cost of plastic production and to create new ways to precisely tune the properties of consumer plastics,” said Renee Sifri, doctoral candidate in chemistry in the laboratory of Brett Fors, associate professor of chemistry in the College of Arts and Sciences.

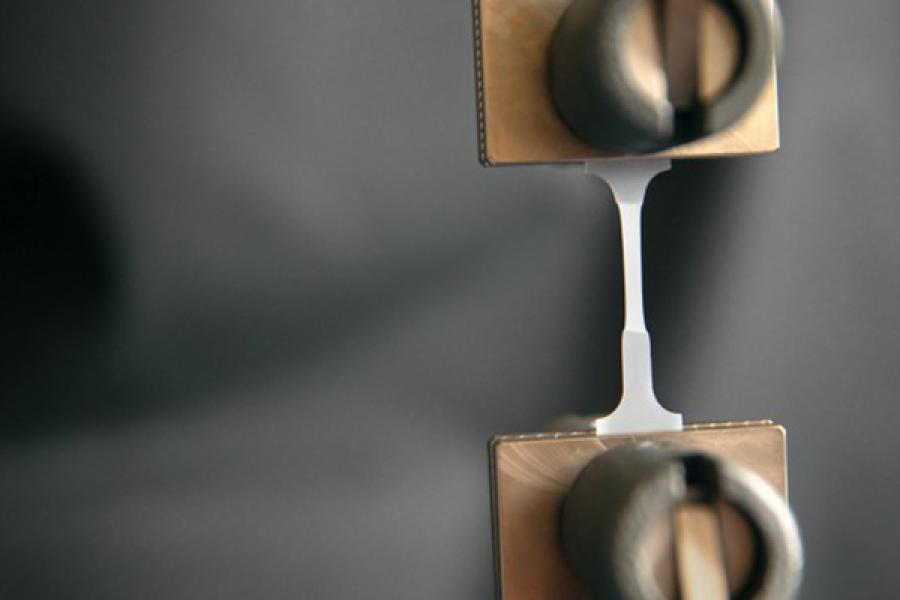

Durable and recyclable, a laboratory high-density polyethylene “dog bone” is tested for tensile strength.

To strengthen plastic products, manufacturers might add extra material in the production and recycling process, which requires energy to melt and mold the plastic into its final form, Sifri said.

Handling high-density polyethylene – known as HDPE, which has a No. 2 recycling symbol – requires a large amount of resources.

“Developing new ways to reduce the amount of plastic production is vital to minimizing plastic waste,” said Omar Padilla-Vélez, doctoral candidate in chemistry in the laboratory of Geoffrey Coates, the Tisch University Professor in the Department of Chemistry and Chemical Biology.

Plastics consist of polymers, which are bonded together chemically into chains. Long chains create stronger materials, Sifri said, while shorter chains allow for easy processing.

Commercial polymers are commonly produced with a range of chain lengths, to optimize performance and processability.

Until now, little was known about the influence of the molecular weight distribution shape on these properties. The new laboratory processes provided precise control over this variable, in turn offering a systematic study of its influence on the material’s physical properties.

“Our work shows promise for lowering the amount of energy needed in processing without compromising polymer strength,” Sifri said. “The take-home message – reduce the processing energy while ensuring the strength is not compromised. That way the plastic containers don’t fall apart.”

To test the tensile strength of the plastic, the researchers molded the new plastic into tiny, flat pieces shaped like dog bones. Tensile testing revealed that the molecular weight distribution (polymer chains) does not impact the strain at its breaking point, which shows that the updated the ability to influence HDPE processing does not compromise material strength.

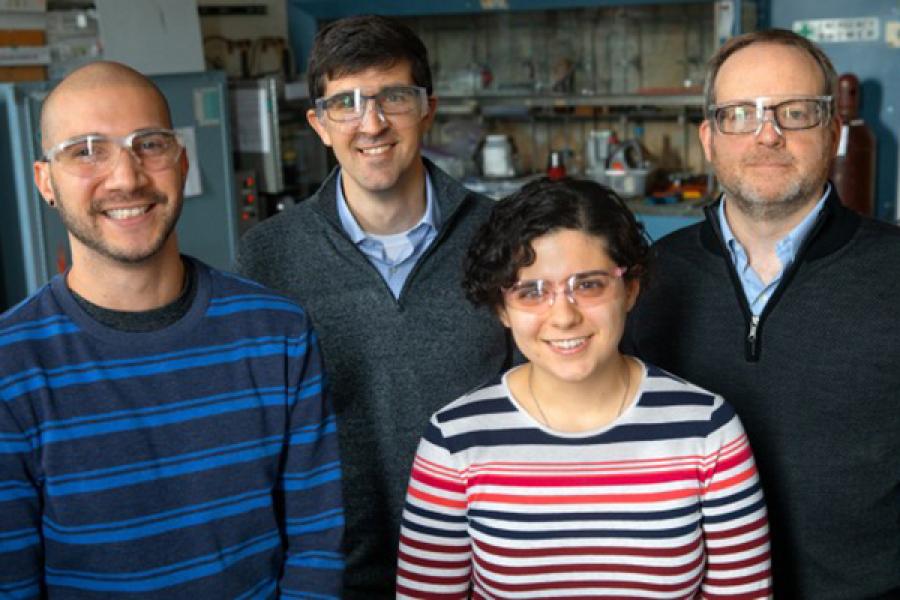

Doctoral candidate Omar Padilla-Vélez, left, associate professor Brett Fors, doctoral candidate Renee Sifri and professor Geoff Coates have demonstrated how to improve high-density polyethylene for a greener world.

Said Padilla-Vélez: “We pulled them apart and noted how much force is required to break them. Our new way lost no strength.”

Sifri, Padilla-Vélez, Coates and Fors authored “Controlling the Shape of Molecular Weight Distributions in Coordination Polymerization and Its Impact on Physical Properties.” The research was supported by the National Science Foundation; the Cornell Center for Materials Research; and Cornell’s NMR Facility in the Department of Chemistry and Chemical Biology.

Read the story in the Cornell Chronicle.