A new technique that combines electricity and chemistry offers a way for pharmaceuticals – including many of the top prescribed medications – to be manufactured in a scalable and sustainable way. The procedure for this technique is outlined in a new paper published Aug. 2 in Nature Protocols.

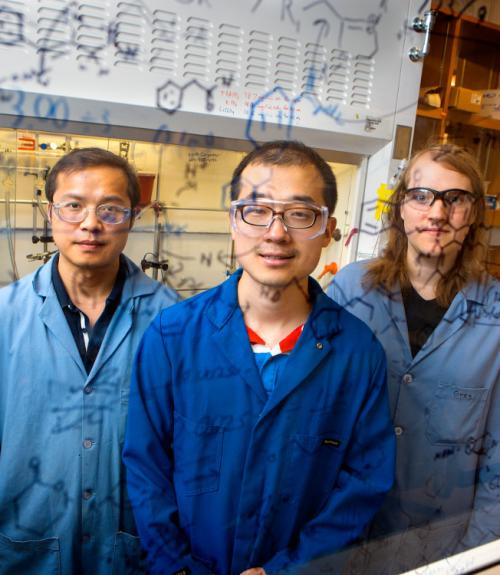

In electrochemical manufacturing, the usual process is to use chemical reagents to provide energy for reactions to occur. Song Lin, assistant professor of chemistry, and his team used electricity to drive the reaction. Because chemical reagents result in waste products that can be toxic, the new process is a more sustainable solution. In addition, renewable energy can be used to provide the electricity needed for their electrically based process.

The Cornell researchers first described their technique in a paper in Science in 2017. Their new paper, said Lin, “gives synthetic practitioners in academia and the pharmaceutical industry a toolbox and protocol to adopt electrochemistry to make complex molecules.” The paper serves as a case study to demonstrate how to use the different apparatuses necessary for the technique, and to outline the setup required to make these compounds. In particular, the protocol is demonstrated with ElectraSyn, a commercial standardized toolkit for electrosynthesis.

“Electrochemistry is an intrinsically sustainable and efficient way to make molecules,” said Lin, the paper’s senior author. “Our new technique will enable the medicinal discovery of new drugs and will reduce waste in industry by making the manufacturing process more efficient.”

The study, “A General, Electrocatalytic Approach to the Synthesis of Vicinal Diamines,” also was written by lead author and postdoctoral researcher Niankai Fu and graduate student Greg Sauer.

Lin recently received a $650,000 Career grant from the National Science Foundation to improve drug production through electrochemistry. He uses his team’s electrochemical methods to establish better reaction technologies to promote formation of carbon-nitrogen bonds from a range of starting materials. More than 85 percent of the top-selling pharmaceuticals have at least one carbon-nitrogen bond, so making carbon-nitrogen bonds in a more sustainable manner, while retaining the chemical selectivity and efficiency of conventional chemical methods, would be a tremendous boon to industry, he said.

This article also appeared in the Cornell Chronicle.