A professor, a postdoctoral researcher and a graduate student hop onto a trampoline.

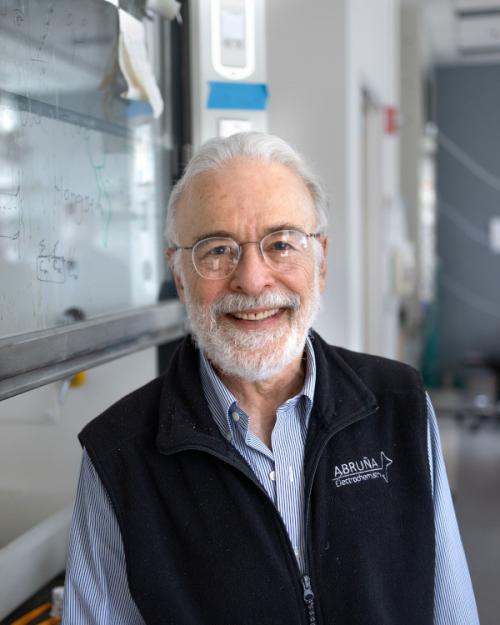

No, it’s not the opening line of a joke. It’s a setup for the explanation of new Cornell-led research involving the wonder material graphene. A group led by Roberto De Alba, graduate student in physics, and Jeevak Parpia, professor and department chair of physics, has published a paper in Nature Nanotechnology regarding yet another application for the versatile, super-strong, super-light material.

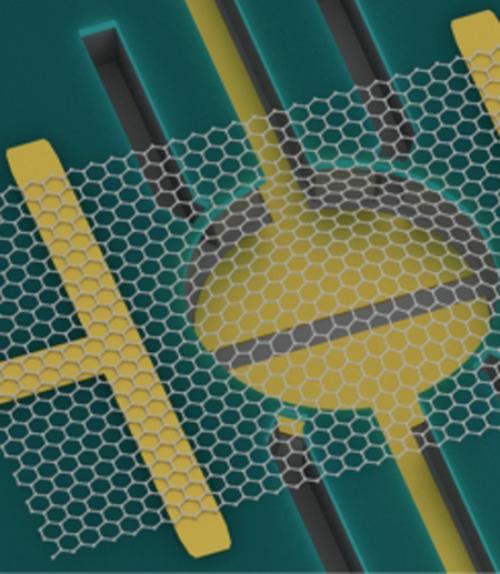

Their paper, “Tunable phonon-cavity coupling in graphene membranes,” was published June 13 and describes the ability to use the graphene’s tension as a sort of mediator between vibrational modes, allowing for direct energy transfer from one frequency to another. De Alba was lead author.

Now, back to the trampoline. Let’s establish that the professor jumps at a slow rate, the postdoc at a medium rate and the grad student at a fast rate. They represent the natural modes of the trampoline, which represents the graphene.

If the professor initiates his slow jumping first, followed by the grad student at a much faster rate, the postdoc – by virtue of the jumping that is already going on – is forced into jumping, at his own rate. What’s more, the professor’s jumps become much higher than they were initially, as energy is transferred to him from the faster jumpers. This scenario won’t actually play out in your backyard, but it takes place in graphene because of its high “elastic modulus” – a material property that means any vibrations will cause large changes to the membrane’s tension.

In applying this concept, the group fabricated graphene “drums” with diameters ranging from 5 to 20 micrometers (1 million micrometers = 1 meter). Those drums can be set in motion either by an alternating electric field or by the random thermal vibrations of their constituent atoms (the same atomic vibrations that define an object’s temperature); the movement is detected through laser interferometry, a method devised several years ago at Cornell in Harold Craighead’s group. Craighead is the Charles W. Lake Jr. Professor of Engineering and a collaborator on this work.

External voltage applied to the graphene membrane acts as a sort of “tuning peg” to control the membrane tension and engineer the coupling needed to control one oscillation mode by exciting the other.

“We’ve shown that there is an effect that will convert energy from one mechanical mode to another mechanical mode,” De Alba said. “It allows us to either damp out or amplify vibrations of one mode by activating the other mode.”

“You’re able to change the fundamental frequency of this object’s motion … essentially its thermal motion, by simply applying voltage,” Parpia said.

The term “phonon cavity” was chosen, De Alba said, because the mechanical effect is similar to that of an optical cavity, which can be used to convert energy from laser light into mechanical motion. Phonons are quasi-particles used to describe vibrations in the same way that photons are particles of light.

This discovery paves the way for the application of graphene mechanical resonators in telecommunication applications – for instance, as frequency mixers.

“And because graphene is only a single atom thick, it has such a low mass that it makes a very good force sensor, gas sensor or pressure sensor,” De Alba said. “It could be used in research labs to study ultra-weak forces.”

In addition, when cooled to near absolute zero, these resonators can play a key role in detection of the faintest quantum signals and in identifying and developing new, secure telecommunication technologies.

Other contributors included Paul McEuen, the John A. Newman Professor of Physical Science and director of the Kavli Institute at Cornell for Nanoscale Science; Isaac Storch, former graduate student in physics; Thanniyil S. Abhilash, postdoctoral researcher in physics; and Aaron Hui ’15, now a graduate student in applied and engineering physics.

This work was supported by the Cornell Center for Materials Research with funding from the National Science Foundation’s Materials Research Science and Engineering Center program. Fabrication was performed in part at the Cornell NanoScale Science and Technology Facility, a member of the National Nanotechnology Coordinated Infrastructure, which is supported by the NSF.

This story also appeared in the Cornell Chronicle.